Grinders

Back to Grinding & Milling

Industrial grinders: raising the bar for zero waste

Our grinders are revolutionizing waste industries. We recognize that industrial waste and waste disposal is a significant environmental challenge, with waste steams arising from agriculture, construction, demolition, manufacturing, and forestry operations.

For a long time, landfill and incineration were default methods of disposal, but environmental pollution, greenhouse gas emissions, and the depletion of valuable natural resources are driving the need for more sustainable approaches. This is where heavy-duty industrial milling and grinding machinery can literally transform waste into valuable fiber.

From our stand-alone low revs per minute (rpm) grinders to mid-speed shredders, super shredders and extremely powerful WSM Titan horizontal grinding systems, our grinders, including all-electric models, can convert even the most challenging urban and waste wood residues to a consistent quality fiber that can be used across the processed wood industries.

Zero wood waste is an ambitious, but achievable goal. Through innovative solutions, cross-industry collaborations, and the right wood processing technology, we can ensure that zero wood waste is not just an ambition, but a reality.

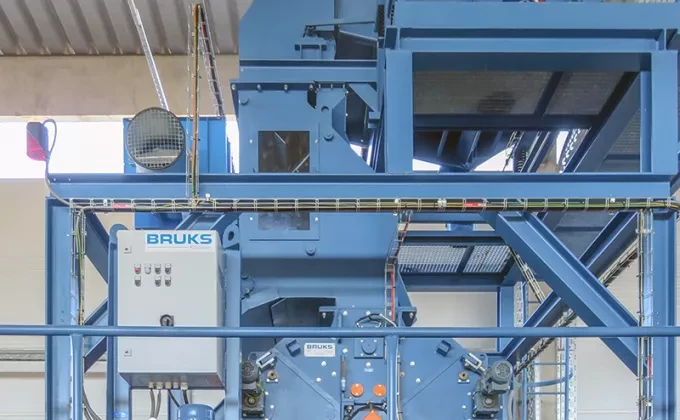

Industrial wood grinders enable rapid, smooth material flows

Our WSM hopper-fed industrial wood grinder offers a complete grinding system, which is ideal for a wide range of high-volume wood and waste wood processing operations. Our industrial wood grinder machine is specifically designed for heavy-use industrial applications and can process pallets and pallet scrap, crating and packaging waste, industrial, construction and demolition wood waste, plastics, plywood and panel scrap, trim ends and edgings.

The WSM hopper-fed industrial wood grinder enables batch feeding, with ‘dump and go’ loads through to automated operations. Our hoppers regulate raw material feeds, which delivers consistent processing speeds and smooth material flows within industrial applications.

WSM industrial wood grinders are easy to install and require minimal foundations, with all the electrical controls and motor starters pre-wired in a single enclosure, factory-tested, and are suitable for indoor or outdoor installation.

High torque, automatic controls

WSM hopper-fed, high-torque industrial wood grinders have a range of automatic controls and operate at low noise levels and at a lower revs per minute (rpm), and include a UL-certified electrical control unit with motor starters, push-buttons, and a programmable logic controller (PLC).

Maintenance is key, and our industrial wood grinder technology has been designed to offer easy access to reversible and replaceable wear components keep maintenance demands to a minimum. We understand that our wood grinding systems operate within some of the most demanding applications in the world.

It is possible to configure our WSM industrial wood grinders to meet the needs of various facilities. Optional index cutters provide multiple wear surfaces for extended service lives and improved performance. Our modular sizing screens, with a full range of perforation sizes and optional baffles, also enable operators to customize grinders to produce any desired finished product. Whatever end product is required, we have the grinding machinery able to deliver it.

Super schredder - link to WSM website

WSM super shredders deliver the ultimate high-performance fiber processing

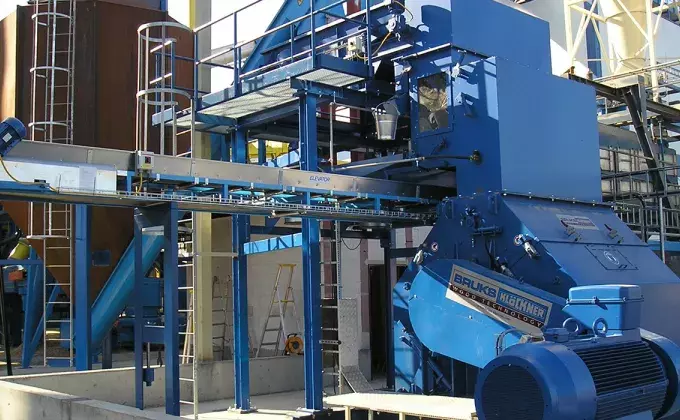

For facilities looking for an industrial shredder for fiber processing, the WSM super shredder offers some of the market’s most powerful and reliable high-volume fiber processing capabilities. The industrial shredder’s processing power often eliminates the need for multiple size-reduction machines, as the WSM super shredder is a single shredding and milling machine for the highest volume applications.

The WSM super shredder can process a huge variety of feedstocks, from hardwood to softwood wood waste and whole pallets, to grass straw. The industrial shredder is a hybrid machine, which offers a unique combination of technologies, delivering the efficiency of a high-speed mill, with the durability of a heavy-duty wood grinder or milling machine. The WSM super shredder has a large 1.2m (48-inch) diameter rotor, which is up to 2.24m (88-inch) in length.

Complete industrial shredder systems can include metering bins, maintenance access platforms, and discharge conveyors. Our WSM super shredder can be configured for full gravity discharge, or an optional plenum flange in the base allows for connection to air discharge or air-assisted onward conveying system.

The WSM super shredder secures its high fiber processing speeds because of its high tip rates, securing raw material flows, increased screen area, and powerful milling action. These capabilities enable the industrial shredder to process high volumes of pre-processed material to a consistently sized fiber for pellet production, biomass power, co-firing, mulching, composting and many other applications such as construction and demolition waste wood processing.

Fiber processing with minimal maintenance

Maintenance is an essential component of efficient fiber processing and fiber processing equipment. The WSM super shredder has been designed to offer reliability and durability under extreme, high-use conditions. Maintenance burdens and operating costs are reduced with dual-pivoting hydraulic housing, which enables easy access to machinery components. For example, it is possible to remove or service the bearings with the rotor in-place thanks to WSM removable bearing support blocks.

Quality components play a significant role in service longevity and wear lives. The industrial shredder is fitted with extra-thick, replaceable and rotatable interior wear liners and modular sizing screens, which can be selected and inter-changed to suit different applications and materials.

Furthermore, decades of service mean that our industrial shredders feature many customer-driven developments that enhance safety and ease of maintenance. These include the ability to rotate hammer tips to expose an unused face. Hammer tips can be easily replaced in the field with an impact wrench. Tip styles can also be exchanged to accommodate different materials. The hammers act against an alloy steel anvil, which is also reversible to extend service lives and easy replacement when necessary.

Mid-speed shredder - link to WSM website

Mid-speed shredders maximize industrial pallet shredding capabilities

Our WSM mid-speed shredders, or pallet shredders, provide the shredding power of larger high-speed units, with greatly reduced fines and dust emissions, noise, vibration, and power consumption.

Pallet shredders are ideal for the industrial processing of waste wood residues, and have an energy-efficient electric drive, reducing pollution from diesel particulates. The electric drive also delivers stepless control. WSM mid-speed pallet shredders deliver more shredding power with less energy than diesel-powered alternatives. Their heavy-duty, high inertia rotor easily shreds pallets and wood waste in a single pass and offers a higher through-put than slow speed units.

The high-performance capabilities of our WSM pallet shredder make it an essential machine within a number of applications including: distribution centers or warehouses that have to handle and dispose of large quantities of used pallets or skids; industrial pallet manufacturers or pallet recyclers with unusable materials and end-of-life timber; wood panel producers, who need to process wood waste and trim recycling; and furniture manufacturers with long trim, ends, or other lineal materials that need to be disposed of.

Within each of these applications, the WSM mid-speed pallet shredder can be the key to efficiently and profitably converting waste into a consistent, enhanced value-added product.

Easy to install and up and running rapidly

The mid-speed shredder is a stationary unit that offers the reliability of electric-powered operation without the maintenance issues of portable shredders. The entire shredding system comprising infeed, shredder, and discharge, is simple to install and rapidly operational.

They have a large 0.86m (34-inch) diameter x 1.42m (56-inch) wide solid steel rotor to ensure superior, consistent particle sizing. Larger incoming material is shredded with our specially developed power-feed mechanism with current limiting infeed control.

Low maintenance requirements and ease of maintenance access, delivered by a pivoting case design, are key attributes of our pallet shredders. Their quality construction and robust components ensure a long service life. These are extended further by both reversible and replaceable heavy-duty cutters. The consistent fiber end product can be discharged to a number of optional arrangements including conveyors, screening and cleaning equipment.

Vertical feed grinders - link to WSM website

Industrial vertical grinders get the most difficult waste processing jobs done

For performance, construction, and durability, WSM vertical grinders offer the market one of the most versatile, powerful wood processing and waste processing solutions. The WSM vertical grinder has been specifically designed for industrial use, from woodworking plants to the largest biomass power facilities.

Many applications require consistently sized raw materials for the process efficiency of their facility. This is often the case across fiber-based industrial applications including pulp and paper manufacturing through the biomass and biofuel. End products size and quality consistency can be delivered with the right wood processing machinery and waste processing solutions, such as industrial vertical-feed grinders.

Our WSM vertical grinders offer simple, energy-efficient size reduction and waste processing flexibility. They can be used for the fine grinding of wood chips for woody biomass pellet feedstock or engineered wood boards or chipboard production, or coarse grinding of bark or wood waste for mulch or biomass fuel. Whatever the application, a WSM vertical grinder can meet wide-ranging demands in product sizing.

Materials that are typically processed by WSM vertical grinders include bark, biomass feedstock, construction and demolition debris, chip overs, food and green waste, lily pads, log ends and log yard debris, pre-shredded wood, sawdust and shavings, trim ends and urban waste wood.

Huge, high-quality rotors

The flexibility of WSM vertical grinders is based on high quality construction and materials, from their heavy fabricated steel housing with extra-thick interior wear liners, and huge rotor assemblies with large diameter shafts, to the highest quality rotor bearings. Together these deliver reliable long-term operation in the most challenging environments.

WSM vertical grinders can be specified with a number of optional features to enhance performance for different applications. This can include a unique WSM infeed chute with ballistics attachment, which helps protect the grinder rotor from tramp metal and large uncrushables.

To ensure the most efficient grind for a given application, WSM vertical grinders can be fitted with different rotor types including open disc, high inertia, and a shredder option. Various hammer types can also be selected including swing style, limited swing, and rigid hammers. Most of these are available with replaceable and reversible hammer tips.

Options to meet specific applications

Our wide range of sizes and rotor configurations ensure the right machine for each application, and delivery of high through-puts, while processing a wide range of feedstock at rates up to 150t/h.

Different screening sizes can also be selected. These modular sizing screens options are available in heavy-duty welded grate bars or perforated screen plate, making them easy to handle and interchange for increased wear life.

In terms of maintenance, in addition to replaceable and rotatable wear parts, WSM vertical grinders have a pivot housing that allows machines to be opened and the infeed chute to remain in place. This improves access for maintenance and provides a safe working space.

Horizontal grinders - link to WSM website

WSM horizontal grinders offers automation and efficiency to complex size-reduction processes

The WSM horizontal grinder offers an effective and efficient way to process wood waste. Furthermore, unlike traditional industrial vertical grinders or chippers, the horizontal feeding mechanism enables it to handle even larger, longer and irregular-sized wood pieces with ease.

So, how does the industrial grinder work? Material is loaded on the infeed conveyor to a WSM powered feel roll, which provides a metered, controlled feed into the horizontal wood grinder. Automatic load-sensing maximizes through-put and improves the handling of surge conditions. Furthermore, the horizontal grinding system eliminates the need for inclined conveyors and infeed chutes.

Our innovative WSM horizontal-feed grinders transform large volumes of scrap wood into usable products. Horizontal grinders convert otherwise wasted material into mulch, biomass fuel, or even raw materials for new wood or fiber-based products, such as panelboard or engineered wood board industries.

Environmental and commercial advantages

There are two key benefits of industrial horizontal grinding machinery. Their ability to process wood scrap as a biomass fuel source contributes to a more sustainable and renewable energy sector; they also divert wood waste from landfills and incineration. Also, horizontal grinders significantly reduce the volume of waste by breaking down large pieces into smaller, more manageable sizes. This reduction in size not only facilitates storage and transportation, but also maximizes the potential use of this processed wood for various applications.

Horizontal grinders process wood for a number of applications, including mulch and landscaping, energy production, and wood composite manufacturing. This versatility creates new opportunities to repurpose and recycle wood waste, minimizing the need for new timber resources. It also directly and indirectly reduces the environmental impact of industrial applications as a whole.

We offer various types of horizontal grinding machinery, including an all-electric horizontal grinder. This model is extremely energy efficient and incorporates advanced automation and control systems, optimizing the entire wood processing workflow. This increased efficiency translates into reduced energy consumption, improved productivity, and cost savings for businesses.

In addition to this, the electric-drive version helps reduce greenhouse gas emissions and air pollution. Furthermore, the horizontal grinder integrates seamlessly into an automated system to deliver various product sizes while reducing labor, handling, and diesel fuel associated with loaders. WSM machinery can be offered with a complete range of feeding, conveying, milling, cleaning, and screening machines that can be integrated into a solution-based system. This approach offers cost savings via high-volume processing, minimizing expenses while ensuring both commercial and environmental benefits.

A combination of heavy-duty components

WSM horizontal-fed grinders offer a comprehensive solution for a wide range of industrial grinding and processing needs. A full range of sizes are available, with processing capacities up to 150t/h.

Their heavy-duty construction delivers proven performance in the most demanding applications around the world. A powered infeed mechanism is a key component in the horizontal grinding system, consisting of a pivoting steel frame around a powered feedroll mechanism. The frame adjusts using hydraulic cylinders maintaining positive downward pressure, while the feed tightly grips the material to provide a positive, consistent and controlled flow of material to the grinder.

The rotor assembly is constructed with heavy-duty machined shaft, rotor discs and alloy steel hammer pins, which are constructed from high-strength alloy steel with drilled and tapped ends for easier removal and exchange.

Abrasion-resistant steel screen bars or perforated plates produce a finished product in a single pass. An extra-heavy interior abrasion-resistant steel wear liner also extends service lives, along with double-row spherical roller bearings and pillow housings. Removable bearing support blocks enable the bearings to be replaced without lifting the rotor assembly.

WSM horizontal grinders have a number of modular and interchangeable options for extended wear life including various screens. An optional pivoting split-housing on larger units, with dual hydraulic cylinders mounted on the sides of the machine, provides easy maintenance and makes the grinder simpler, faster and safer to open.

WSM horizontal low-rpm grinders deliver a high-torque, powerful processing system

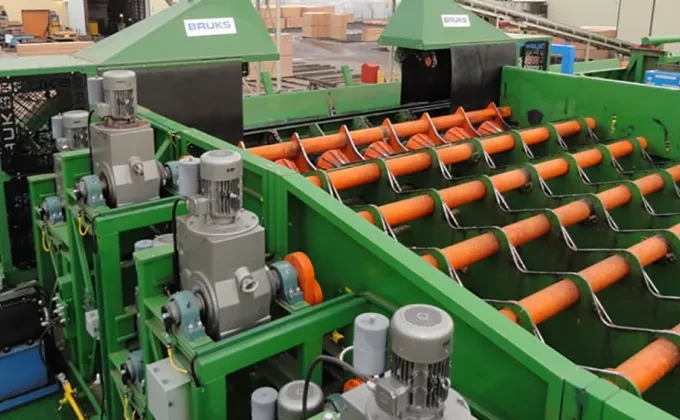

Our horizontal low revolutions per minute (rpm) WSM grinding system can be delivered with a belt or vibrating infeed conveyor, power feed mechanism, grinder, and control panel, which makes it perfect for processing long edgings and panels, as well as shorter trim material.

WSM low rpm wood grinders can deliver operational advantages from small to medium-sized wood waste generators, up to the largest composite board manufacturers.

The low-profile design of the WSM horizontal grinder makes it easy to locate in a plant, saving space and eliminating costly support structures or special foundations. The slow speed, high torque cutting action requires lower horsepower, which also minimizes noise levels.

WSM low rpm horizontal grinders are available in a full range of sizes with 30cm (12 inch) up 1.88m (74 inch) wide feed openings. All electrical controls and motor starters are pre-wired in a single enclosure, factory-tested, and suitable for indoor or outdoor installation.

Their robust, mill-duty construction make these grinding machines some of the toughest on the market, with easy access and reversible and replaceable wear components, including multiple cutter options, keep maintenance to a minimum and tailor the grinders to their application.

WSM low rpm horizontal grinders can process pallets and pallet scrap, panel trim, reject panels, and trim ends and edging. The tight tolerances between cutters and anvil deliver a high-performance shearing action for consistent output.

They can also be fitted with an optional ferrous metal remover to help prevent damage downstream and maximize end product value. Modular screens and indexable cutters extend wear life and reduce maintenance costs.

Bruks-Siwertell

Bruks-Siwertell