Ship loaders that meet ordinary to extraordinary needs

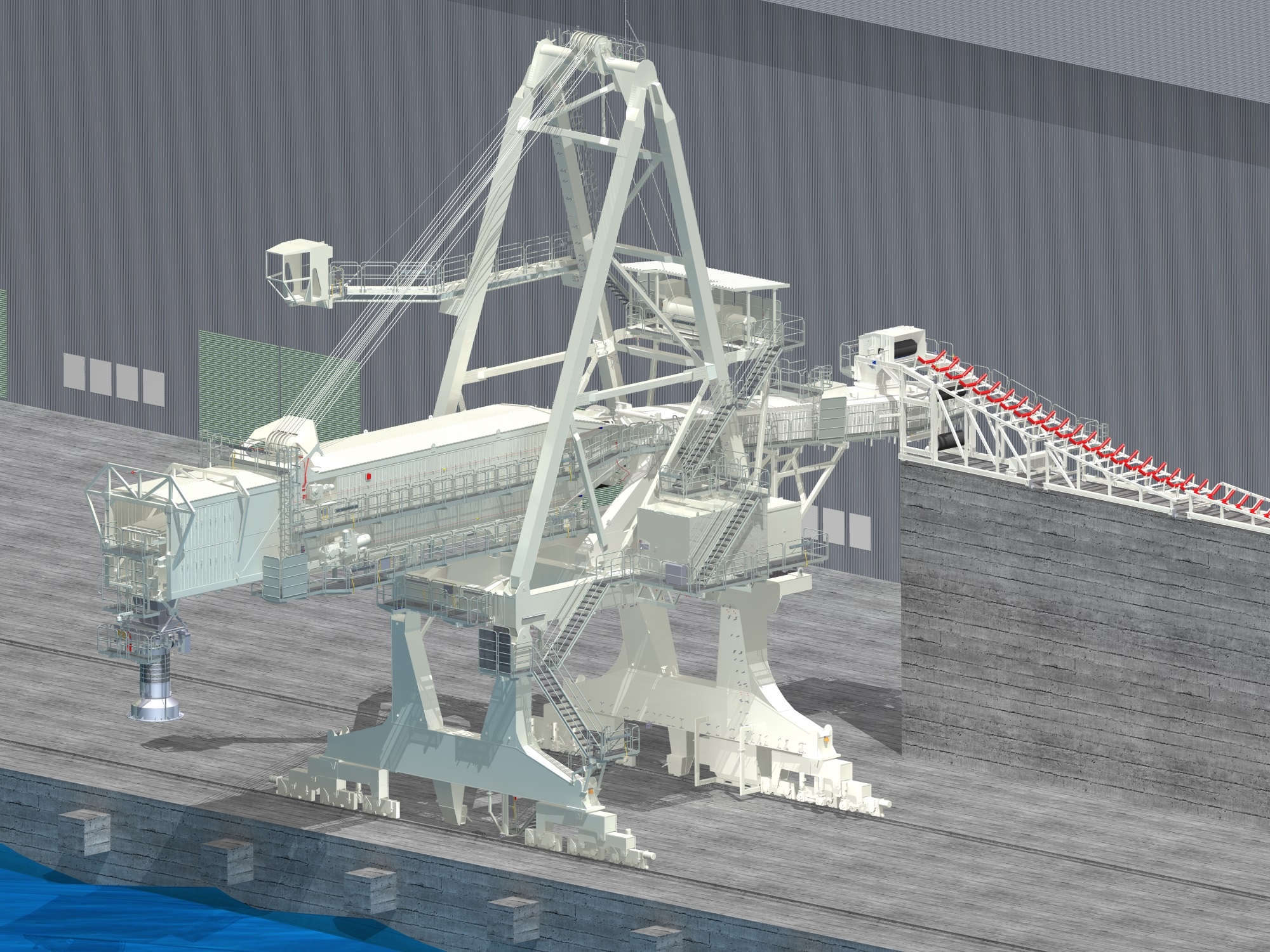

Bruks Siwertell’s market-leading ship loaders are based on screw, aeroslide or belt conveying technologies and are delivered as stand-alone equipment or as part of terminal systems. All deliver effective bulk carrier ship loading solutions.

The dry bulk handling market demonstrates a range of unique elements. No two ports are exactly the same in terms of their cargo mix or volumes, bulk carrier ship loading requirements, blueprint, or local climate. Bruks Siwertell designs and delivers ship loading systems that are tailored to serve its customers’ needs, rather than expecting them to adapt their operations to limitations in their equipment.

Above image: Siwertell ship loader installed in Australia. Read more about the customer case here.

Ship loaders are supplied as stationary or rail-traveling units with telescoping and slewing configurations. For even greater access to all parts of the hold, shuttling and slewing screw-type ship loaders can be supplied with a scissor-arm arrangement. We can deliver ship loading systems with capacities as high as 12,000t/h.

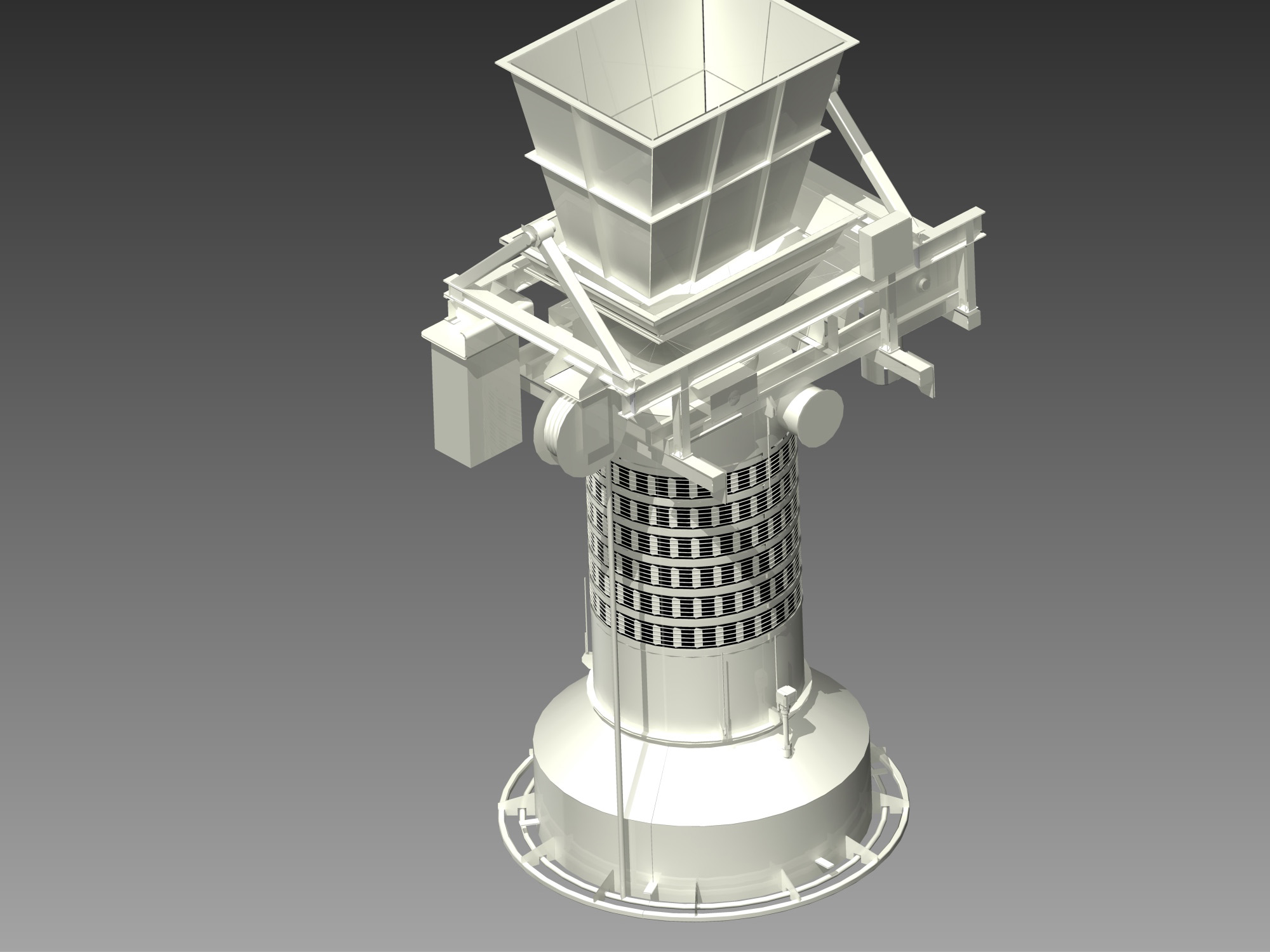

Loading chute

Siwertell ship loaders are equipped with loading chutes appropriate to the materials being loaded. Chutes are often telescopic and their length is automatically-adjusted depending on the level of material in the ship’s hold. They are specially-designed to prevent any dust emissions even when handling powdery, dusty materials.

Operator's cabin

The ship loader can be operated either from the cabin or using a remote control unit directly from the side of the ship’s hold. Both arrangements offer excellent views of the loading area. The cabin is mounted on an arm at the same level as the loading boom and it slews along with the loading boom. It is fully-insulated and equipped with a heating fan and an air-conditioning unit to provide the operator with a comfortable work place, even in extreme weather conditions.

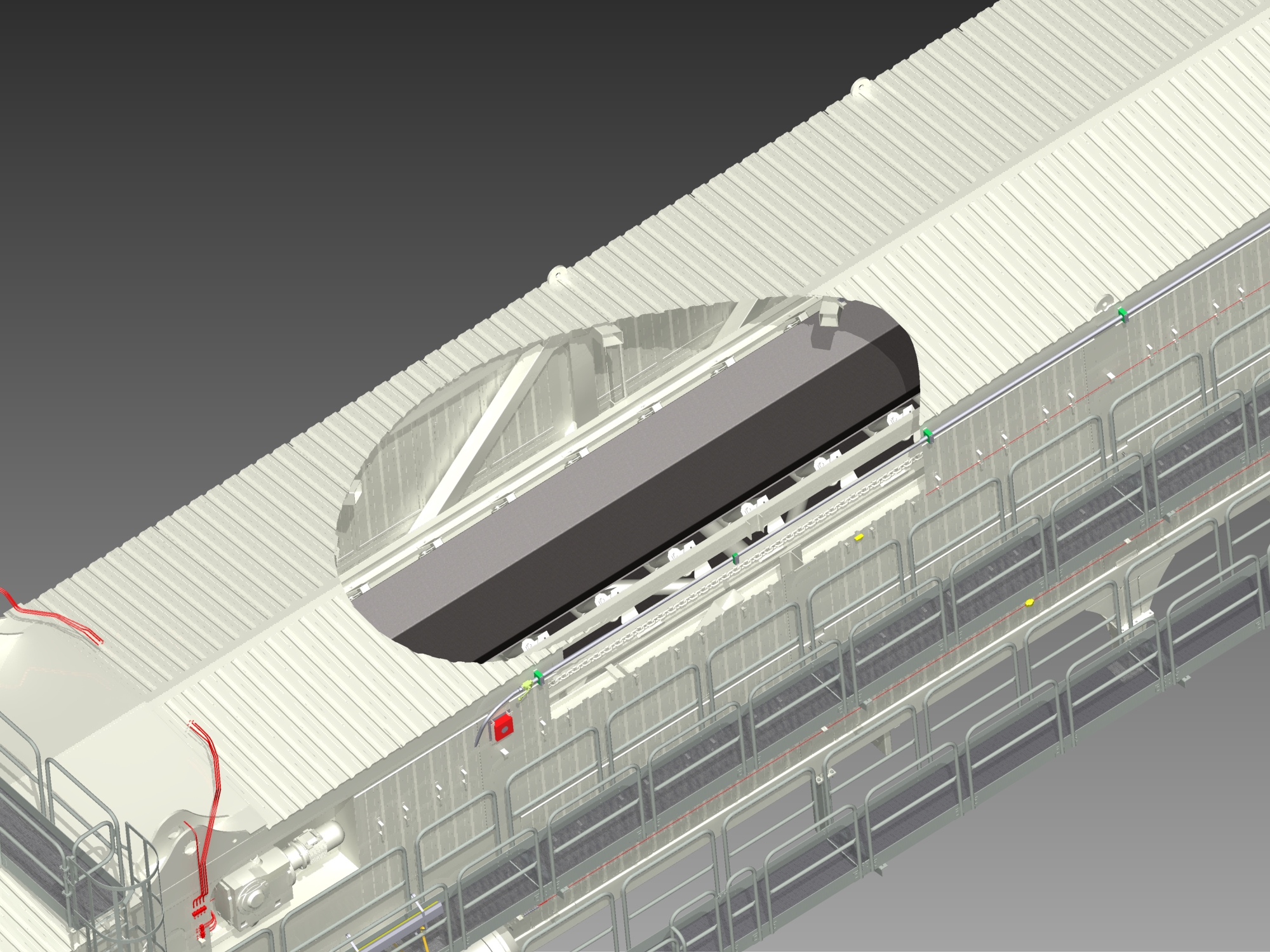

Loading conveyor

The loading conveyor can be screw, aeroslide or belt type; all are totally-enclosed to prevent any dust creation or spillage. When a belt-type conveyor is used, we can offer a telescopic loading conveyor.

Electrical system

The electrical system is installed in an insulated electrical housing equipped with a heating fan and an air-conditioning unit. It is made up of elements such as low voltage switchboards with a motor control center, contactors, a programmable logical control-system and the human machine interface.

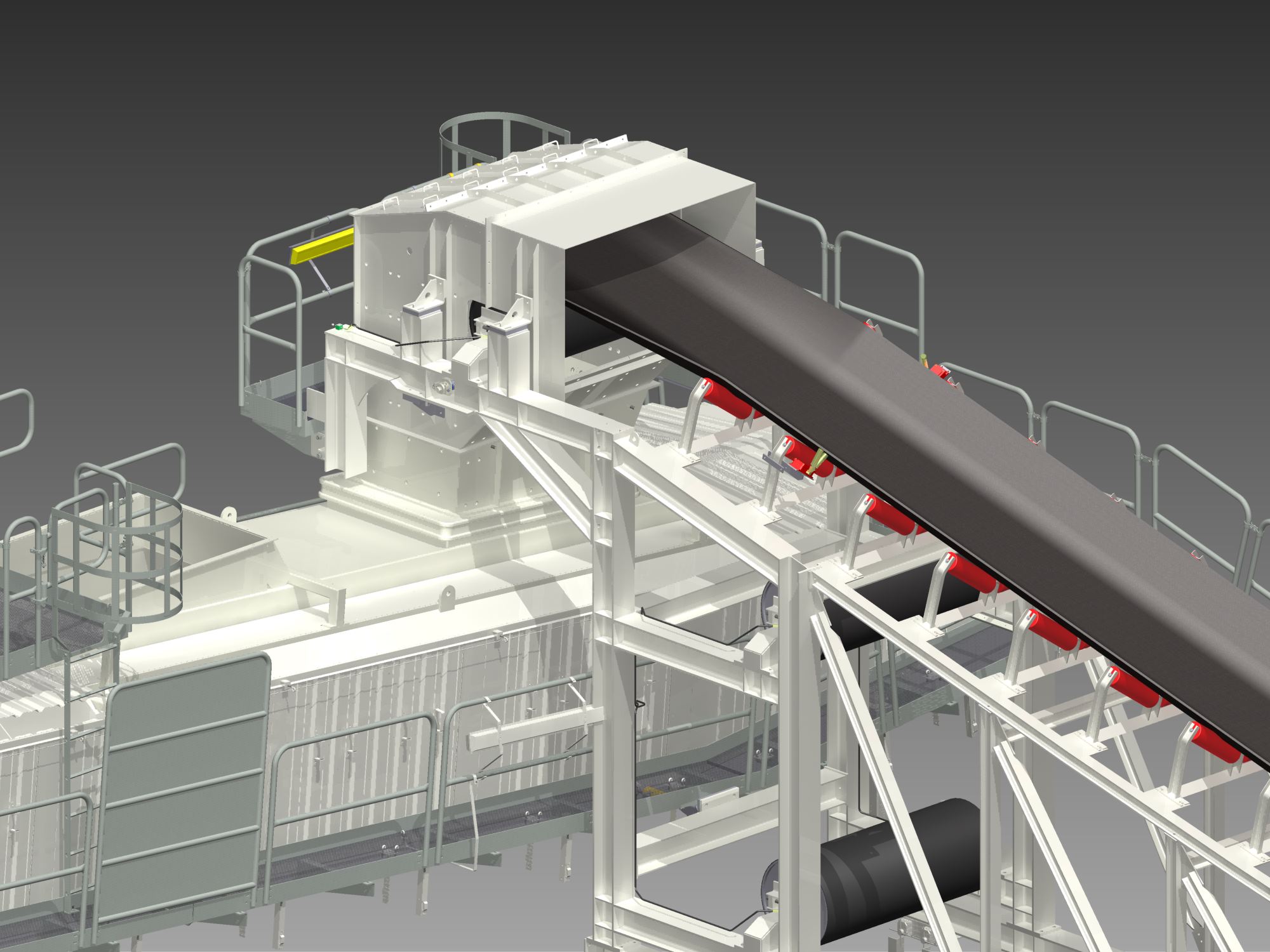

Tripper

A tripper is used to transfer bulk material from the shore conveyor to a traveling ship loader. The tripper travels on rails and is towed by the ship loader.

NEXT-GENERATION SERVICE AGREEMENTS

Our commitment to customer service means that we stand by our deliveries throughout their lifetimes. By selecting the support elements that you require, our planned service agreements are tailored to meet your needs. They are applicable for dry bulk handling equipment including ship unloaders, loaders, conveying systems and terminal operations.

SHIP LOADING CHUTE

Siwertell ship loaders are equipped with loading chutes appropriate to the materials being loaded. Chutes are often telescopic and their length is automatically-adjusted depending on the level of material in the ship’s hold. They are specially-designed to prevent any dust emissions even when handling powdery, dusty materials.

OPERATOR'S CABIN

The ship loader can be operated either from the cabin or using a remote-control unit directly from the side of the ship’s hold. Both arrangements offer excellent views of the ship loading area. The cabin is mounted on an arm at the same level as the loading boom and it slews along with the loading boom. It is fully-insulated and equipped with a heating fan and an air-conditioning unit to provide the operator with a comfortable workplace, even in extreme weather conditions, during bulk carrier ship loading operations.

SHIP LOADING CONVEYOR

The ship loading conveyor can be screw, aeroslide or belt type; all are totally enclosed to prevent any dust creation or spillage. When a belt-type conveyor is used, we can offer a telescopic ship loading conveyor.

ELECTRICAL SYSTEM

The electrical system is installed in an insulated electrical housing equipped with a heating fan and an air-conditioning unit. It is made up of elements such as low-voltage switchboards with a motor control center, contactors, a programmable logic control-system and a human machine interface. All are designed to offer smooth, responsive and intuitive control over ship loading operations.

TRIPPER

A tripper is used to transfer dry bulk material from the shore conveyor to a traveling ship loader. The tripper travels on rails and is towed by the ship loader.

CLEAN AND COST-EFFECTIVE SHIP LOADERS

Bruks Siwertell’s range of ship loaders and ship loading equipment are cost effective and kind to the environment. They are supplied with ship loading spouts designed to suit the material to be handled, reducing dust and spillage to a minimum. These include double-walled flexible spouts and cascade-type bellows with a lightweight, compact design. Bruks Siwertell ship loaders can be ordered as standalone products or as part of a complete bulk terminal solution.

DIFFERENT CARGOES CALL FOR DIFFERENT CONVEYOR TECHNOLOGIES

Screw-type loaders: A screw-type ship loader is totally enclosed and often used for handling powdery and dusty dry bulk materials such as cement, clinker, sulfur and minerals. Screw-conveyors load dry bulk carriers up to Panamax size.

find out more about the materials we handle

Aeroslide loaders: Totally enclosed aeroslide ship loaders are generally used to handle easily-fluidized materials such as cement, dry fly ash and alumina. They can load bulk carriers up to 80,000 dwt. Aeroslide ship loaders must be installed on a downward slope, as gravity is essential to their operation. They can be ideal when height restrictions are a major factor.

Belt-conveyor loaders: A Bruks Siwertell belt conveyor ship loader can handle a broad range of commodities including lumpy, granular and sticky materials, such as coal, ores, minerals, grain, feedstuff and fertilizers. They benefit from low energy consumption and can load bulk carriers up to 300,000 dwt. Belt conveyors can be covered to protect cargo and minimize environmental impact and spillage.

VERSATILITY AND PERFORMANCE

Bruks Siwertell’s ship loaders are tailored to your needs, with a focus on ship loading performance. Outstanding performance relates not only to capacity, but also to efficiency, economy, the environment, safety and careful cargo handling.

We offer versatile systems. For example, a ship loader can be designed to be equally environment-friendly and efficient loading either cement or clinker; two commodities used by the same industry but with totally different characteristics. This versatility extends to vessel size; a ship loader can provide exactly the same effectiveness loading coastal barges or large ocean-going dry bulk carriers.

GOING SUPER-SIZED

If asked: just how much material can a Siwertell machine load directly into a ship’s holds? Using the new high-capacity ship loader, Bruks Siwertell’s answer is: in the space of an hour, 12,000 metric tons of iron ore, or 8,000 metric tons of coal. The new ship loader serves some of the largest bulk ships in the world; iron ore carriers of up to 300,000 dwt and 230,000 dwt coal carriers.

Going super-sized

If asked: just how much material can a Siwertell machine load directly into a ship’s holds? Using the new high capacity loader, Bruks Siwertell’s answer is: in the space of an hour, 12,000 metric tons of iron ore, or 8,000 metric tons of coal. The new loader serves some of the largest bulkers in the world; iron ore carriers of up to 300,000 dwt and 230,000 dwt coal carriers.

Complete bulk terminal solutions

Bruks Siwertell designs solutions for complete bulk terminals. We will work closely with you to make sure our solutions fit with your specific needs. Our high-capacity, high-efficiency unloaders, loaders, conveying systems and stacking and reclaiming systems stand to provide you with substantial cost savings from reduced operating times.

Bruks-Siwertell

Bruks-Siwertell