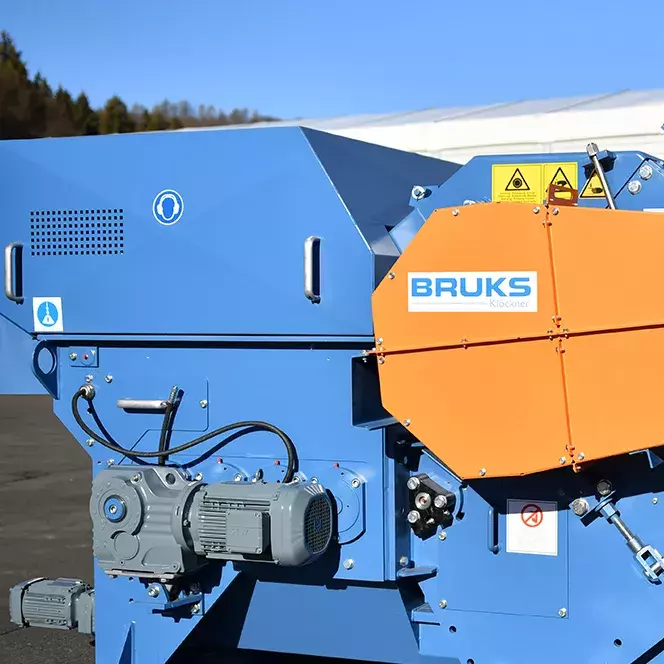

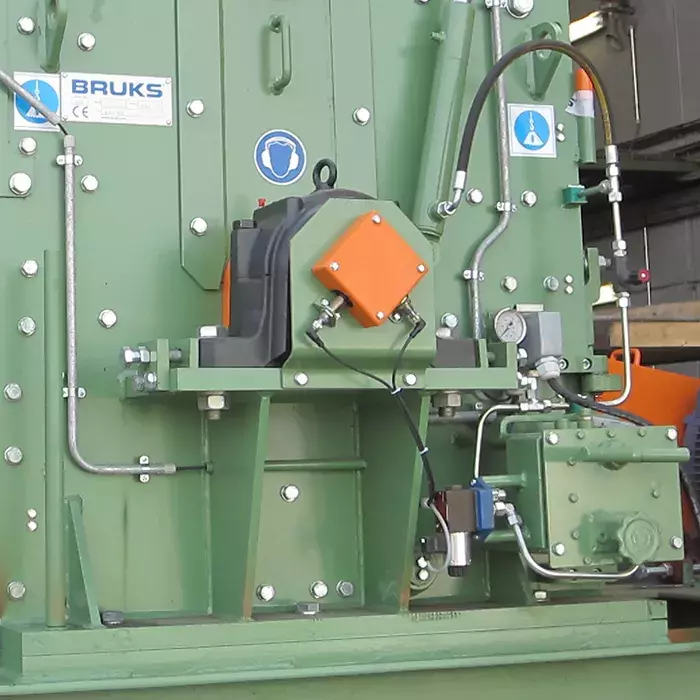

Bulk handling and wood processing for every operation

Bruks Siwertell's products and solutions fulfill your operations within ship unloading, ship loading, bulk conveying, stacking and reclaiming, truck unloading, chipping, milling, screening and wood-residue processing.

We love engineering and technical challenges. Our focus is on designing and providing you with the most efficient, profitable and environment friendly systems. We can tailor make our solutions according to your specific needs, and can also offer standardized solutions with quick deliveries.

Bruks Siwertell’s market-leading technology can be found across the world in industries ranging from bulk handling, biofuel and bioenergy to board, saw mill, pulp and paper.

Bruks-Siwertell

Bruks-Siwertell