Pulp and paper

On a roll: Revolutionizing pulp and paper industry processes with innovative technologies

One of the oldest documented industries is pulp and paper; a sector that has seen significant changes over the centuries. Its ability to respond to market forces is remarkable, along with the technology that supports the mechanical pulping process, and other pulp and paper industry processes that drive sustainable paper production.

With the worldwide focus on sustainability and sustainable paper production, the pulp mill, paper mill, and packaging industry is seeing increased demand for fiber-based products to replace other products, including plastics.

Furthermore, the current boom in e-commerce has driven a huge increase in the need for container board, cardboard and carton board packaging, and with ever-more retail transitioning online, this trend has little chance of slowing down, making sustainable paper production critical, along with innovating pulp and paper industry processes.

Raw materials are prized commodities, so keeping material costs low and returns high, is crucial. Bruks Siwertell understands that yields are key and has a portfolio of wood-processing technology and pulp and paper solutions, which offer the very best capabilities for this industry.

The right tools for the job

Our pulp and paper solutions and mechanical pulping process equipment has enabled the pulp and paper industry to meet market shifts by refining processes, automating where feasible, boosting efficiency where possible, and making the best use of raw materials.

We all have a stake in ensuring nothing is wasted in the production of wood products. Bruks Siwertell works closely with its customers to make sure they always have the right tool for the job, delivering the most sustainable paper production possible, and driving the highest levels of operational efficiency.

Pulpwood to product

Different trees make different kinds of paper. For printing and writing, a mixture of hardwood and softwood fiber is needed to give them flexibility and strength. Hardwood trees, such as oak and birch, are ideal for tissues, while softwood species such as fir and pine have stronger fibres and are destined for use in corrugated carboard boxes and bags.

Our wood-processing technology and equipment for the mechanical pulping process handles hardwood and softwood trees and can process both dry and green wood. We have served the pulp and paper industry for decades, delivering pulp and paper solutions that unload, load, receive, screen, shred, chip, process, convey, store and stack and reclaim the pulpwood material required to meet the needs of this versatile market, and ensure sustainable paper production.

Automated woodyards reduce operating costs

To improve operating efficiencies, reduce environmental impact material degradation, many mills are switching from managing woodyards with manual equipment, such as dozers, and moving to automated systems.

We offer tailored systems that will meet the capacity demands of any mill. For example, a Bruks Siwertell fully automated woodyard can include Bruks truck dumpers, with covered receiving hoppers, circular blending bed stacker reclaimers (CBBSRs), sawdust metering towers; and complete conveyor systems, including market-changing systems like Bruks air-cushion conveying technology, The Belt Conveyor™.

Market-changing conveyors

Bruks Siwertell a long history of supplying all kinds of conveying systems to the pulp and paper industry. This includes horizontal, vertical and inclining screw conveyors, as well as chain conveyors.

Bruks Siwertell’s air-supported conveyor technology offers some of the most significant material transfer advantages that the industry has seen. These include extremely low maintenance and running costs along with very high levels of environmental protection.

The Tubulator™ is the perfect choice for long transport, offering a 40 percent increase in capacity, width-for-width, over a traditional idler belt conveyor. With more than 700 installations since its introduction over 30 years ago, it is a well-proven technology for pulp and paper processes, performing in all environments, from tropical heat to Arctic cold.

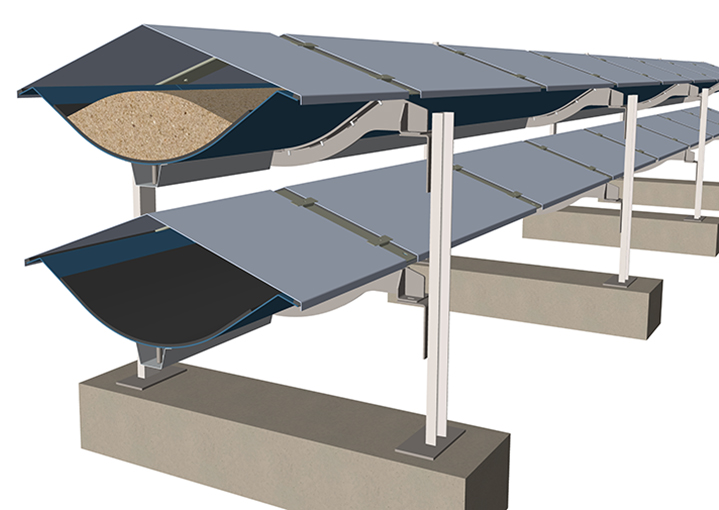

Another air-supported conveyor innovation that serves the pulp and paper industry process is The Belt Conveyor™. It innovatively combines the use of air-cushion technology with standard belt conveyors, ensuring low-friction, high-capacity conveying that offers minimal equipment wear and very low operating costs.

Both the Tubulator and The Belt Conveyor use air cushions and eliminate the use of idlers, or rollers, to support the belt over the conveying distance, and contribute to high levels of operational efficiency and sustainable paper production.

Chipping away: efficiency advances

The chipper or chipping mill plays a critical part in pulp and paper industry processes and sustainable paper production. Bruks Siwertell is at the forefront, supplying facilities worldwide with quality wood chips from our range of heavy-duty Bruks disc and drum wood chippers.

The size and variety of the wood to be processed are usually the deciding factors for which technology to select, but some facilities require much greater control over chip size, while others need very low running costs. For the pulp and paper industry, the disc chipper often takes center-stage.

Bruks disc chippers carefully slice the wood in such a way as not to damage the delicate wood-fibres needed for the production of pulp. They also cut at the optimum angle for ensuring that each individual chip is uniform size, between 20 and 50mm.

For higher capacities and shorter logs, the drop-fed Bruks drum chipper can handle up to 1,000m³ per hour. Our drum chippers can process the most difficult-to-handle wood and produce a quality end product. To reduce oversized chips after a screening process, drum chippers can be used as re-chippers, the Bruks Klöckner re-chipper.

The wood chips from our machines can be used for high-quality applications in pulp mills as well as by the veneer industry, particle board producers and as microchips for direct drying in pellet mills.

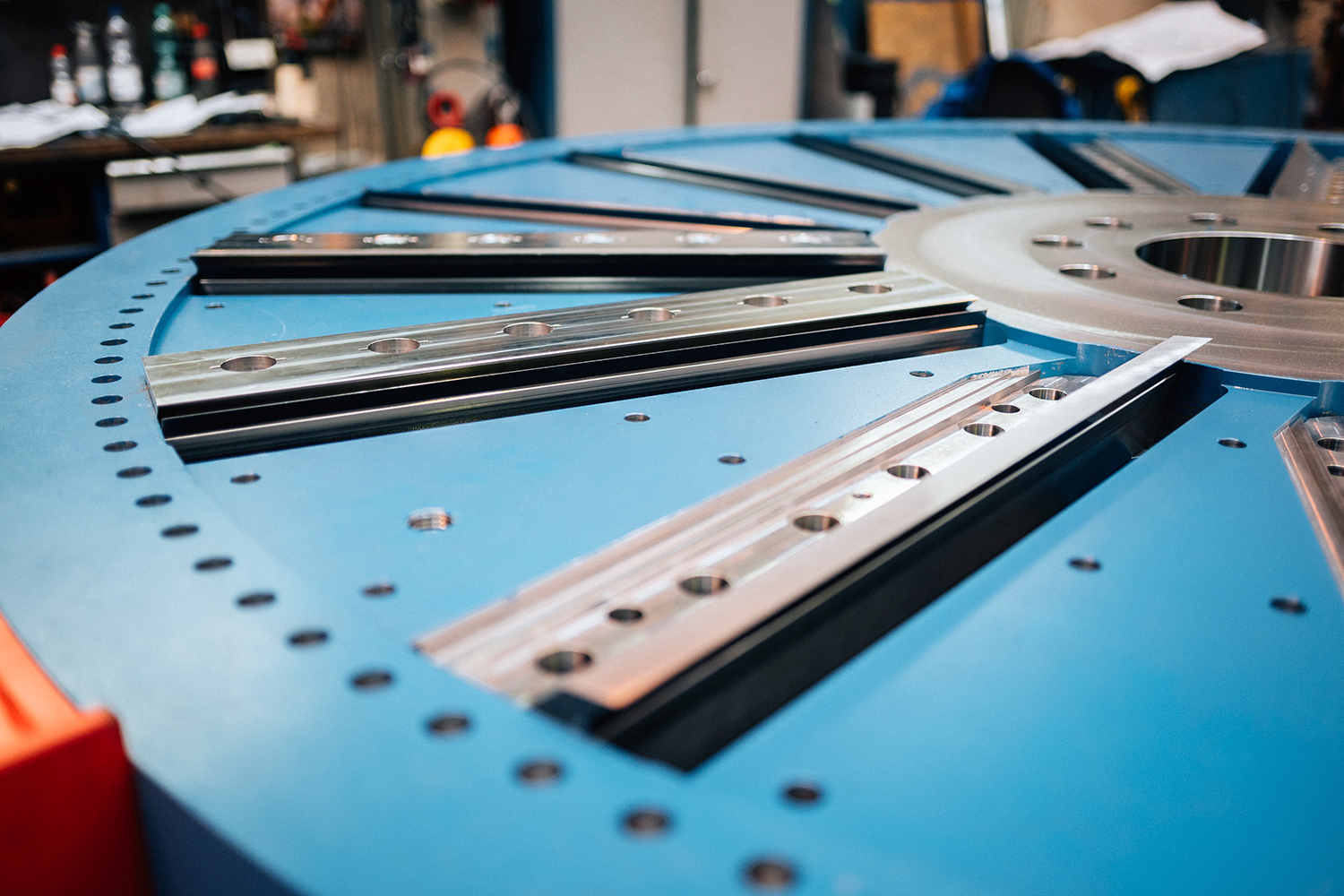

Disc chipper enhances meet modern needs

Bruks Siwertell has undertaken a comprehensive disc chipper enhancement program to meet changing market demands.

Features include an extended setting range for chip length and thickness. The high quality of wood chips is achieved through a scissor cut of knife-and-counter-knife across the fiber, with the cutting angle defined by the disc chipper’s geometry. Integrated chipping discs are included with diameters of 1.5, 2.0, 2.5 and 3.0m.

Vast volumes managed with ease

Our stacker reclaimer systems are seen presiding over huge piles of wood chips at many forestry and wood-processing facilities, and have been delivering critical levels of material handling automation to the pulp and paper industry for decades.

Our fully automated range of Bruks stacker reclaimers help operators to get the best out of their yard space, operating round the clock arranging wood chips into piles. For example, CBBSRs, piles are built continuously in a 360-degree rotational pattern, where successive layers of material are laid down using a stacking conveyor that pivots through a complete circle as the pile grows. This automated technology enables the oldest materials to be reclaimed first, ensuring consistent quality throughout, and excellent performance at the plant.

Pulp and paper industry solutions: Our speciality

WSM machinery is well-recognized in the pulp and paper industry as it meets the ever-increasing demand for high-volume processing of renewable and sustainable feedstocks. Converting raw material and processed wood waste and forestry residuals into pulp, woody biomass, and other value-added fiber products requires reliable, robust machinery with minimal maintenance requirements to keep the mill operating.

Feedstock materials vary greatly based on region and availability with some being simpler to process, while others are more difficult with unique challenges, ensuring that they can be ready and in optimum condition for conversion and the mechanical pulping process.

Decades of experience in successfully grinding, screening, and processing a wide range of materials including wood waste, wood scrap, lumber, stumps, sawmill residuals, sawdust, wood shavings, wood chips, forest residuals, woodyard residuals, used wood, and quick-growing trees from tree plantations, ensures that we have the expertise and equipment to eliminate waste and deliver the highest yields.

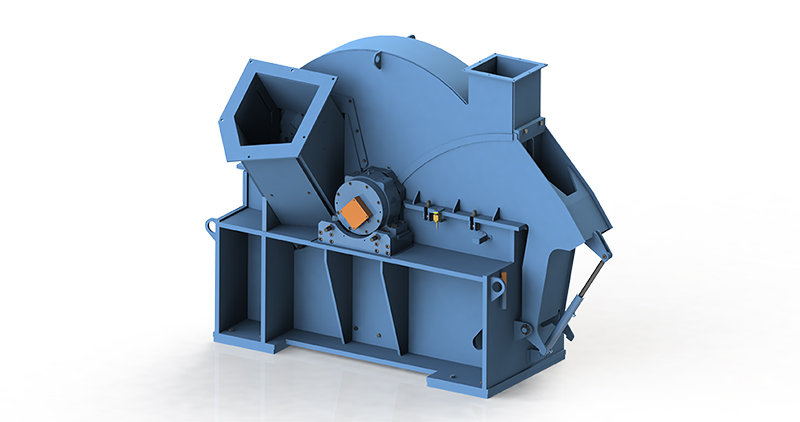

WSM pulp and paper industry solutions include a no-knife re-sizer, shredders, hammermills, wood waste grinders, oscillating chip screens, disc screens, vibrating screens and conveyors, and trommel screens, which deliver superior results in the most demanding environments.

For example, WSM vertical grinder and shredders are particularly effective at processing and supporting green waste recycling. For the pulp and paper industry, they ensure that green waste and wood residue processing is as efficient and reliable as possible, performing in some of the most demanding applications around the world. Innovative design and maintenance features, include the WSM pivoting hog housing, enabling easy maintenance access.

Our experienced pulp and paper industry experts, engineering, and manufacturing capabilities combine to ensure that equipment is designed, configured and manufactured to deliver the best solution for your industrial pulp and paper needs, based on incoming feedstock material and finished product specifications. We ensure that the right machines are specified, and can deliver a complete line of WSM equipment.

Nothing going to waste

Every business wants to reduce waste; but the forestry business is one where almost no waste need truly be wasted; there is value even in dust. Reducing waste also increases efficiency.

To help meet the increased demand for renewable and replaceable fiber-based products and sustainable paper production, the pulp and paper industry demands tough, mill-duty grinding, shredding, screening, and processing equipment that provides heavy-duty units, offering reliable, long-term operation.

With an increased competition for fiber raw materials, pulp and paper industry processes and operators also need to be able to handle and convert a wide variety of incoming feedstock including forest residues, laminated veneer lumber (LVL) and plywood trim and offcuts, slabs, bark, logyard and woodyard debris, trees, stumps, and pallets.

In addition to the pulp and paper industry these mixed raw materials can be used for biomass feedstock, boiler fuel, compost, landscape material, and wood pellets or densified fuel.

Bruks Siwertell offers the widest range of feedstock processing and conversion technologies for producing valuable wood fiber products for the pulp and paper industry, including Bruks and WSM hammer mills, screens and griding machinery. Configuring individual machinery components maximizes the efficiency of applications. We can also design a fully integrated system including conveyors and access platforms.

Screening solutions for effective sorting

The Bruks and WSM range of screening and waste wood residue processing machinery works together to ensure that the best use is made of the available materials.

Our disc-scalping screens are the ones most likely to be used for first-line screening at a pulp and paper mill. Their modular design makes it possible to optimize them for specific tasks and chip sizes.

Mills can choose from a number of screening devices, including oscillating chip screens, disc screens, and vibratory screens, which can operate virtually maintenance-free for decades at a time. Rejects can be taken to hammer mills and grinders, which can be used to process any forestry waste and turn them into a valuable product.

Integrated, turn-key solutions

Some pulp and paper industry facilities require stand-alone equipment, such as a disc or drum chipper, hammer mill and grinder, while others look for an integrated approach. This delivers a very high degree of operational efficiency and performance.

In the US, an integrated system of Bruks equipment secures a biomass-fuel supply line for Georgia-Pacific’s Naheola pulp and paper mill, ensuring the facility’s future sustainability and capacity increases.

Bruks Siwertell’s delivery includes two drive-over truck dumpers with receiving hoppers, six partially-covered belt conveyors, a hog and screen tower, a vertically-fed Bruks Rotom hammer hog with disc scalping screen, a three-meter circular overpile stacker reclaimer (COSR), and an emergency reclaim hopper.

Bruks-Siwertell

Bruks-Siwertell