STATIONARY AND MOBILE INDUSTRIAL WOOD CHIPPERS: MATCHED TO MEET YOUR NEEDS

The high-performance capabilities of industrial wood chippers are vital for supporting the increasing demands of the renewable energy industry. Wood chips offer a more uniform combustion profile than solid log fuels, and can be delivered directly to a boiler, gasifier or other energy conversion system in a consistent steady flow.

For many bioenergy plants, wood chips are the end of the line, for pellet manufacturing plants they are the raw materials. To compete for sustainable fuel production, both require consistent performance, reliability, and efficiency from their wood-processing equipment; exactly what our advanced industrial wood chipper technology ensures.

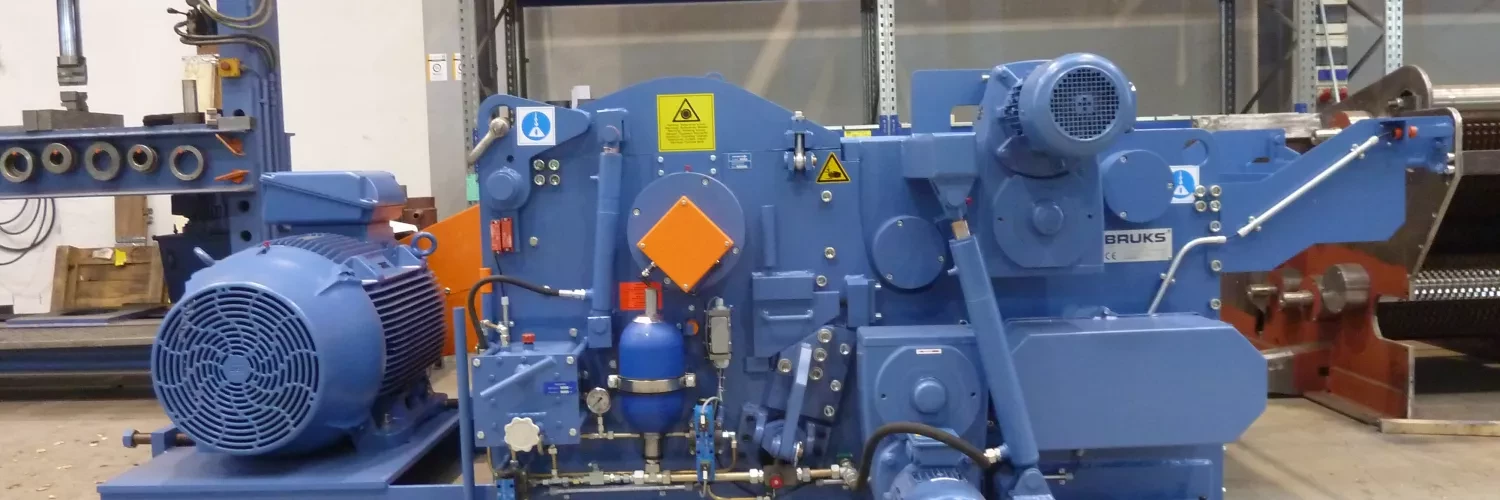

Our heavy-duty machines, including both stationary and mobile wood chippers, are at the forefront of the chipping industry, with wood processing and manufacturing facilities depending our technology to deliver high-capacities and consistent quality wood chips.

MAXIMIZING CHIPPING EFFICIENCY FROM INFEED TO DISCHARGE

All our industrial wood chipper machines use powerful hydraulically-operated infeeds, which process the wood either through a drop-fed or horizontal-fed drum or disc chipping unit. Mobile units offer rugged flexibility for in-forest chipping or agility within the terminal. When the material has been cut, chips pass through a chip screen into a hydraulically powered chip accelerator, maximizing chipping efficiency and production volumes. From the accelerator, wood chips are discharged through the chip tube.

We have combined the best of our market-leading technologies to deliver industrial wood chipper machines that offer the ideal balance between power and torque. Precise power and torque curves are extremely helpful when it comes to attaining the lowest possible fuel consumption during chipping.

The size and variety of the wood to be processed are usually the deciding factors for which wood chipper is selected by an operator, with some industries requiring much greater control over chip size, while others needing very low running costs. All our chipping systems ensure that wood flows smoothly through the chipper, minimizing dust, wear and energy consumption.

QUALITY MACHINES DESIGNED FOR DECADES OF SAFE SERVICE

Safe operation is a priority, with guards and safety systems on chipping machines benefiting from decades of proven design. This extends to quality components, which have been designed for easy, safe maintenance. For example, cutting knives are readily accessible and wear parts are exchangeable.

Bruks Siwertell supplies industrial wood chippers as standalone units and as complete packages, ranging in sizes and designs, and tailored with technology configured to optimize their performance depending on their application in the field.

With our commitment to ongoing service support, we expect our industrial wood chipper machines to serve your operations for decades. The proven capabilities of Bruks industrial chippers have become relied upon across hundreds of installations worldwide, with end users very satisfied with their ability to deliver high-capacity wood chips at minimal costs.

Bruks-Siwertell

Bruks-Siwertell