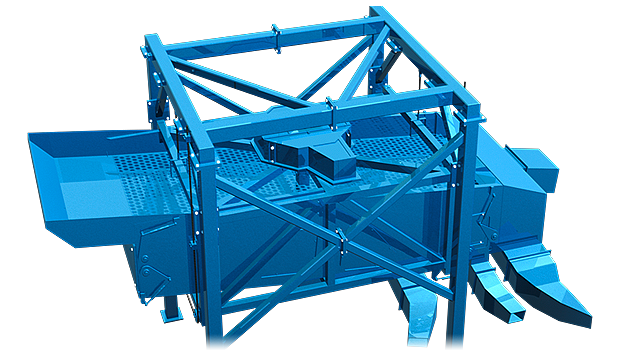

Gyratory free swinging screen

Back to Screening

Oscillating motion makes light work of material screening

Bruks gyratory free-swinging screens and WSM oscillating screens have a global reputation for extremely efficient screening. Gyratory swinging screens and oscillating screens are used within numerous industrial applications, but are an essential piece of machinery for high-volume, high-capacity size sorting in sawmills, pulp and paper manufacturing, pellet plants, and engineered wood board and panelboard production.

Gyratory swinging screens and oscillating screens are particularly well-suited for handling all types of woody biomass including wood pellets, wood chips, sawdust and wood shavings.

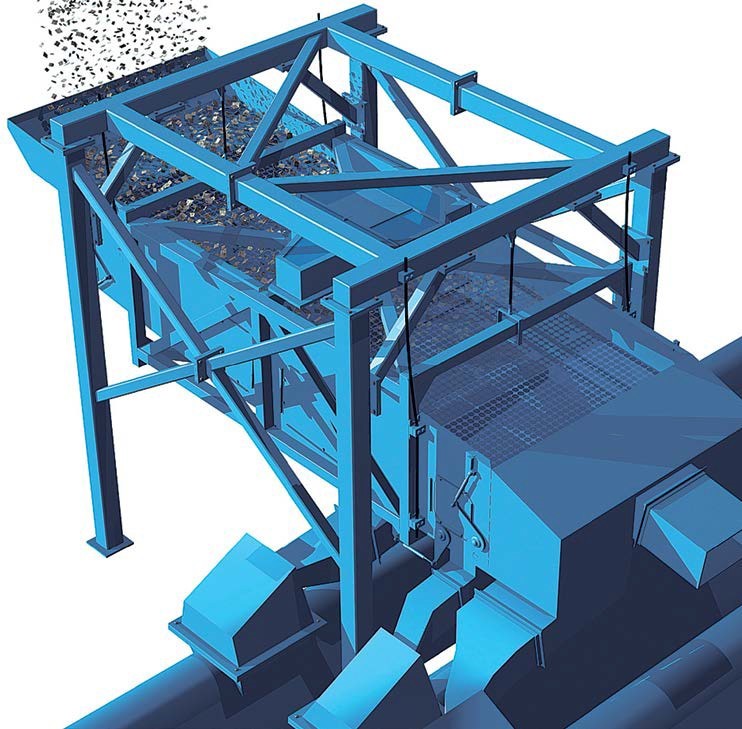

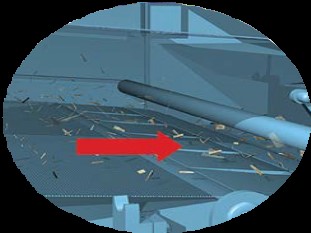

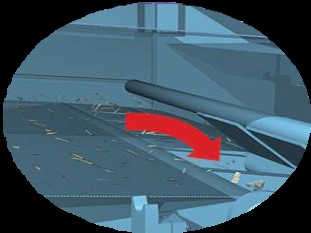

Most gyratory and oscillating free-swinging screens are built around an inclined and suspended box frame that contains one or several perforated screen plates. The frame oscillates in a horizontal plane, with material being fed onto the upper end. As it moves the material slides down the plates, with the desired sized material being able to drop through the perforations of the screen plates. Over-sized material is retained and can be rechipped or otherwise processed.

Many different configurations of plates and perforation sizes enable operators to achieve just the right sized particles and fiber for their use. Gyratory free-swinging and oscillating screens are well known for their low rates of material degradation as material gently slides down the plates with the oscillating motion. They also offer service longevity and add downstream process efficiency and ensuring that no raw material is wasted.

Our industry-leading Bruks gyratory free-swinging screens and WSM oscillating screens are well known for their size sorting consistency and durable performance.

Accurate separations set industry standards

Bruks gyratory free-swinging screens are relied upon worldwide for their ability to separate wood-based materials such as chips, pellets, pin chips or sawdust, into two to four size categories.

Gyratory screening maximizes profits by ensuring the highest possible yields and are available in sizes ranging from 2.5 to 24m2. Our punched plate or wire mesh screen plates are easily accessed and changeable.

Benefits of good design

The screening motion for our gyratory free-swinging screens is generated by a motor-driven, rotating counterweight, delivering a high-capacity throughput. The bulk material is delivered via an inlet chute, which is designed to spread a load over the entire width of the screen and reduce material flow to an optimum level.

The system comprises a screen box, suspended by steel cables, which contains two or three screen decks with decreasing hole sizes. The top deck consists of perforated screen plates; other decks usually have wire mesh-type plates in place, which ensures superior separation of fines and pin-chips. High volumes and loads are accommodated by the integral strength of the plates and mesh.

For some units, the screen decks have a stepwise decreasing inclination, which leads to decreasing transport speeds. This design delivers an impressive combination of high capacities with highly accurate screening. Other units are specified for an ingenious control mechanism that makes it easy to vary the proportion of an accepted fraction in a load, or to discharge a separate fraction of processed material entirely.

All our screen decks are exchangeable and come with a variety of perforations adapted to individual requirements. Optional flop gates in the discharge chute are also available. These optimize sawdust and pin chip separation.

Next-generation oscillating screen technology

WSM oscillating screens, including the WSM oscillating super screens, also have a global reputation for reliable sorting of wood fractions.

For high-volume chip screening, bark screening, or precise classification of sawdust and shavings for animal bedding, the WSM oscillating screen is a preferred technology across a variety of industries.

WSM flat oscillating screen machinery offers up to three screen decks for multiple separation points, with customized discharge chutes, and a screen area up to 3.66m (12ft) x 6.10m (20ft). Production capacities from 8 to 80 units per hour, ensure that the WSM oscillating screen can be configured to meet the largest wood processing applications, and provide the efficient and effective classification of a variety of wood materials.

All WSM oscillating screens are available with a full range of options and are designed to meet the individual requirements of each operation. From high volume chip screening to precise classification of particleboard furnish, to bark screening for mulch, WSM flat oscillating screens offer proven performance and reliable, low maintenance operation in demanding environments. All WSM screens are constructed using the highest quality materials and manufacturing techniques.

Smart screening design features and customizable options

WSM oscillating screens can process wood chips, bark, mulch, particleboard furnish, sawdust and shavings, and trim ends and edgings. Decades of industry experience influence the design of WSM oscillating screens including: a readily accessible belt drive assembly for easy maintenance; adjustable tilt basket assembly to maximize production capacity; a counter-weighted drive for smooth, balanced operation; a centralized drive lubrication system, which provides safe access for lubrication during operation; and easily replaceable heavy-gauge steel screens, with operators being able to choose between perforated or wire mesh screens with variable wire diameter as required for accurate material classification.

Optional extras include a ball deck assembly to prevent wet material from blinding screen openings and a precision-machined eccentric drive to provide a consistent, smooth oscillating motion. Optional top covers can also be specified for enhanced dust control and material containment.

WSM oscillating super screens

The WSM oscillating super screening system offers a next-generation screening solution. It delivers even higher rates of through-put and robustness, with a redesigned basket, which is 15 percent lighter than previous models. This reduced weight translates into less machinery wear and tear and fatigue, therefore delivering a longer machine life.

Other design features include oversized hangers, which extend durability. The drive unit has also been relocated to outside the basket for easier access and maintenance, and unobstructed material flow. A stainless-steel slope pan base keeps material flowing, by preventing it sticking. This is ideal for exiting fines and moves material up to four times faster than models without this design.

Whatever material and capacity each application requires, we can configure a screening system to meet those needs and maximize material throughput and production.

Free-Swinging Chip Screen

-

Data -

Average capacity, m3/h -

SG5-3 -

60 -

SH5-4 -

60 -

SH8-3 -

120 -

SH11-3 -

250 -

SH11-4 -

250

-

Data -

Momentary capacity, m3/h -

SG5-3 -

100 -

SH5-4 -

100 -

SH8-3 -

200 -

SH11-3 -

300 -

SH11-4 -

300

-

Data -

Max capacity for separation of fines, m3/h -

SG5-3 -

12 -

SH5-4 -

12 -

SH8-3 -

25 -

SH11-3 -

50 -

SH11-4 -

50

-

Data -

Screening area, m2 -

SG5-3 -

5 -

SH5-4 -

5 -

SH8-3 -

7,6 -

SH11-3 -

11 -

SH11-4 -

11

-

Data -

Electrical motor (kW) -

SG5-3 -

4 -

SH5-4 -

4 -

SH8-3 -

5,5 -

SH11-3 -

7,5 -

SH11-4 -

7,5

-

Data -

Net weight, kg -

SG5-3 -

1600 -

SH5-4 -

1800 -

SH8-3 -

3200 -

SH11-3 -

4000 -

SH11-4 -

4500

-

Data -

Screening fractions -

SG5-3 -

3 -

SH5-4 -

4 -

SH8-3 -

3 -

SH11-3 -

3 -

SH11-4 -

4

| Data | SG5-3 | SH5-4 | SH8-3 | SH11-3 | SH11-4 |

|---|---|---|---|---|---|

| Average capacity, m3/h | 60 | 60 | 120 | 250 | 250 |

| Momentary capacity, m3/h | 100 | 100 | 200 | 300 | 300 |

| Max capacity for separation of fines, m3/h | 12 | 12 | 25 | 50 | 50 |

| Screening area, m2 | 5 | 5 | 7,6 | 11 | 11 |

| Electrical motor (kW) | 4 | 4 | 5,5 | 7,5 | 7,5 |

| Net weight, kg | 1600 | 1800 | 3200 | 4000 | 4500 |

| Screening fractions | 3 | 4 | 3 | 3 | 4 |

Bruks-Siwertell

Bruks-Siwertell