Bruks Siwertell wins repeat wood chipper contract from Paged

24 Nov 2020

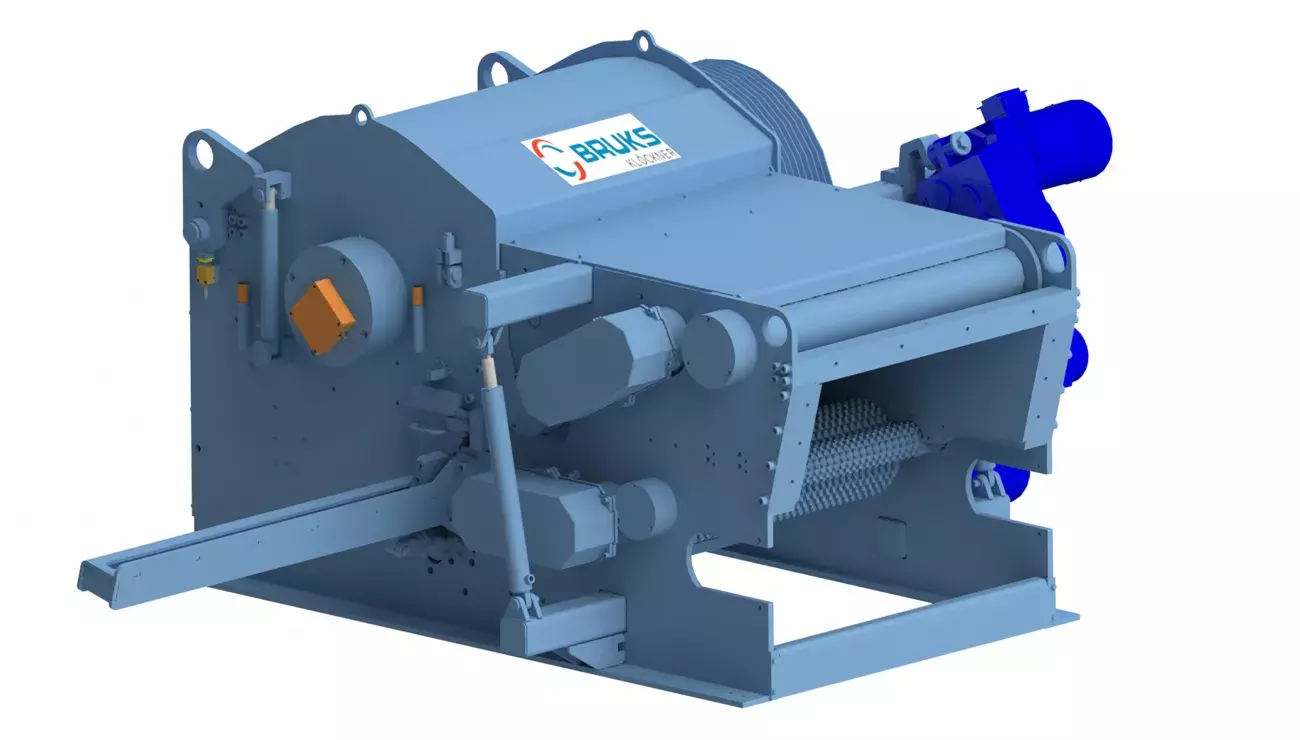

Bruks Siwertell has been contracted to replace an existing wood chipper with a new higher-capacity model to increase processing capabilities and maximize efficiency, profitability and sustainability for returning Polish customer, Paged.

Due for delivery in early 2021, the drum chipper will be used to reprocess veneer production waste and feed the biomass boiler at the Paged Pisz Sp. z o. o veneer and plywood production facility in Kwiatowa, Pisz, north-east Poland; one of the company’s two Polish production sites, with the other in Morąg.

The new machine will replace a previously installed Bruks chipper, which was delivered in 2000, and has worked over 100,000 hours, serving three shifts a day. Bruks Siwertell also replaced Paged Morąg’s old chipper in 2018.

“Both original Bruks chippers have served the company very well, and Paged, once again turning to Bruks Siwertell, is a great endorsement of the technology, its performance and reliability,” explains Karol Banach, Investment Specialist, Paged. “Paged Pisz’s old chipper is currently still in operation, but to keep pace with production demands, a higher capacity model was needed.”

The replacement system will have a loose chips processing capacity of 60m³/h, delivered through an increased infeed height and width, and a more powerful 160kW main motor. It will enable Paged to increase veneer and plywood production, feeding the biomass boiler and producing the heat needed for production processes.

“Paged is focused on sustainability,” says Andreas Hürten, Sales Manager, Bruks Siwertell. “It is trying to reduce its reliance, as much as possible, on fossil fuels, using waste wood as a valuable resource. With the increased capacity delivered by the new chipper, we can help Paged to maximize the facility’s wood-processing capabilities, ensuring the most efficient and profitable operation.”

In addition to the new drum chipper, Bruks Siwertell will deliver an infeed belt conveyor equipped with a metal detector to prevent any tramp material damaging the equipment. Meanwhile on the other side of the chipper, Bruks Siwertell will install a scraper conveyor for transporting the wood chips onward and connecting them with Paged’s existing conveyor network.

Please contact us for more information

Area Sales Manager, Bruks Klöckner GmbH

Stefanie Müller

+49 1712406067

Bruks-Siwertell

Bruks-Siwertell