Bruks Siwertell adds service tower equipment to ship unloader range

25 Aug 2020

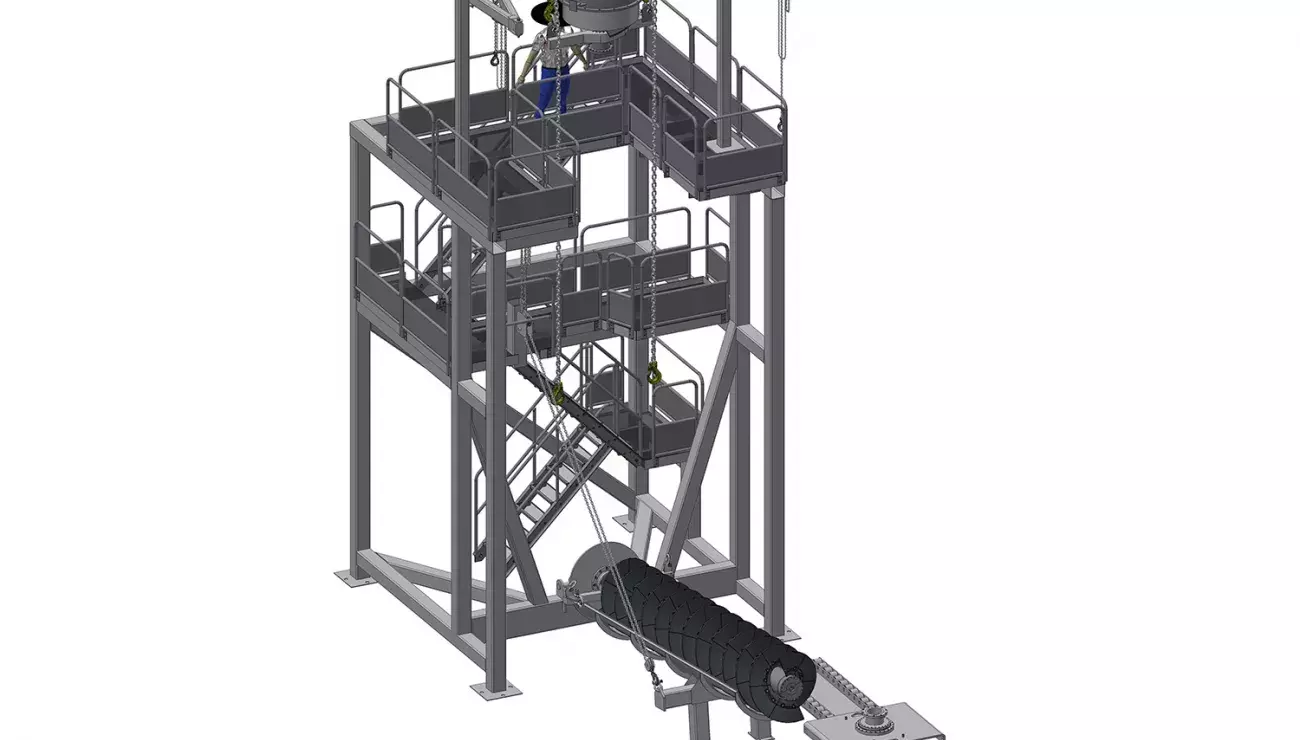

Bruks Siwertell has launched a new service product that promises to substantially simplify and lower the cost of fitting replacement screws on its market-leading Siwertell ship unloaders.

“All our equipment, including service strategies, benefit from decades of continuous research, development and improvement, and the latest product is a service tower for replacing screw sections on our Siwertell ship unloaders,” says Björn Ohlsson, Manager, Bulk Terminals Design and Engineering, Bruks Siwertell.

“It offers a number of key advantages,” he explains. “Principally, the service tower eliminates the need for cranes, which are traditionally used to lift the screws. This reduces costs and improves the overall safety of the operation. Also, because the tower is specifically designed for the task, the whole process is faster.”

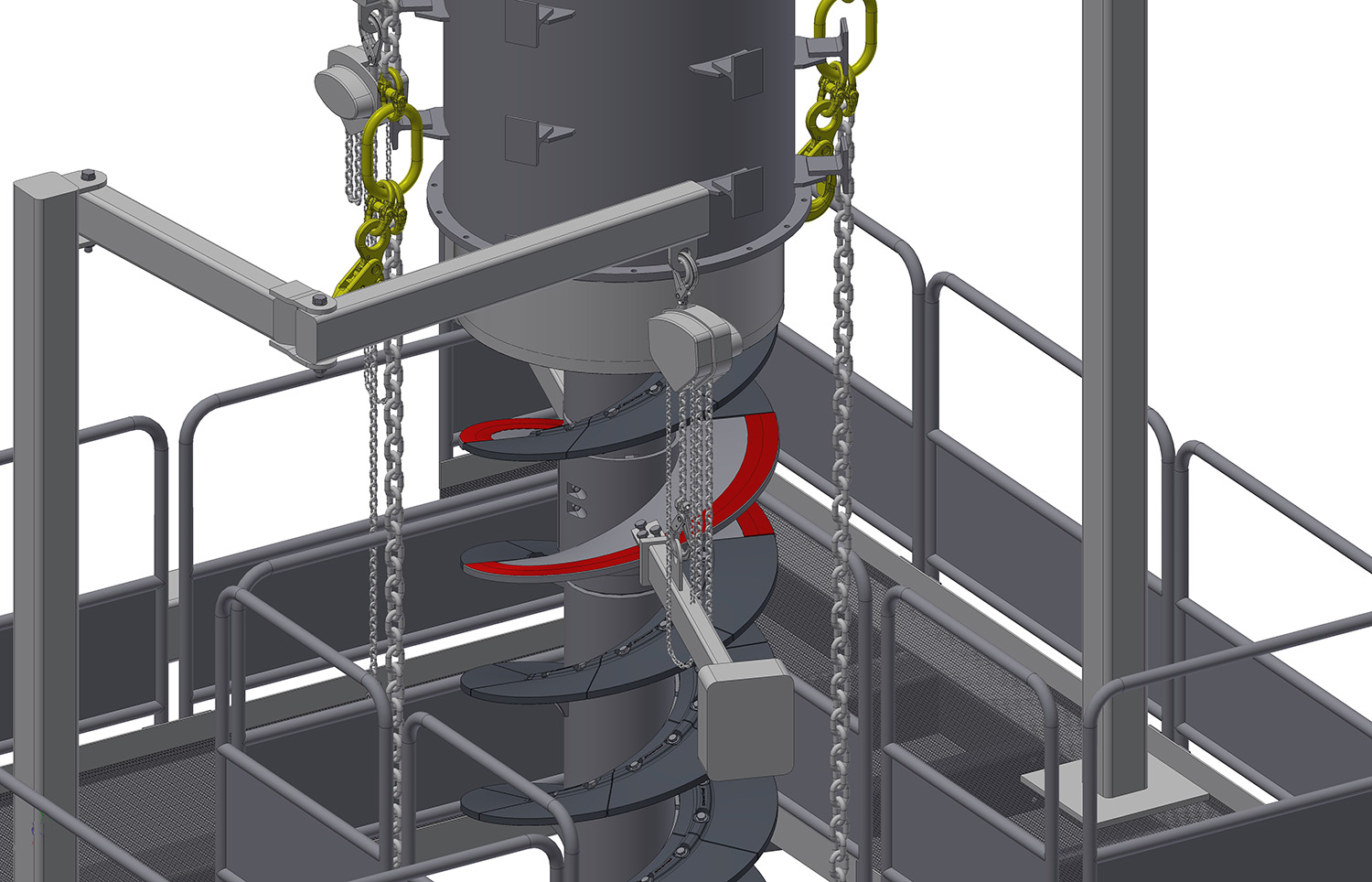

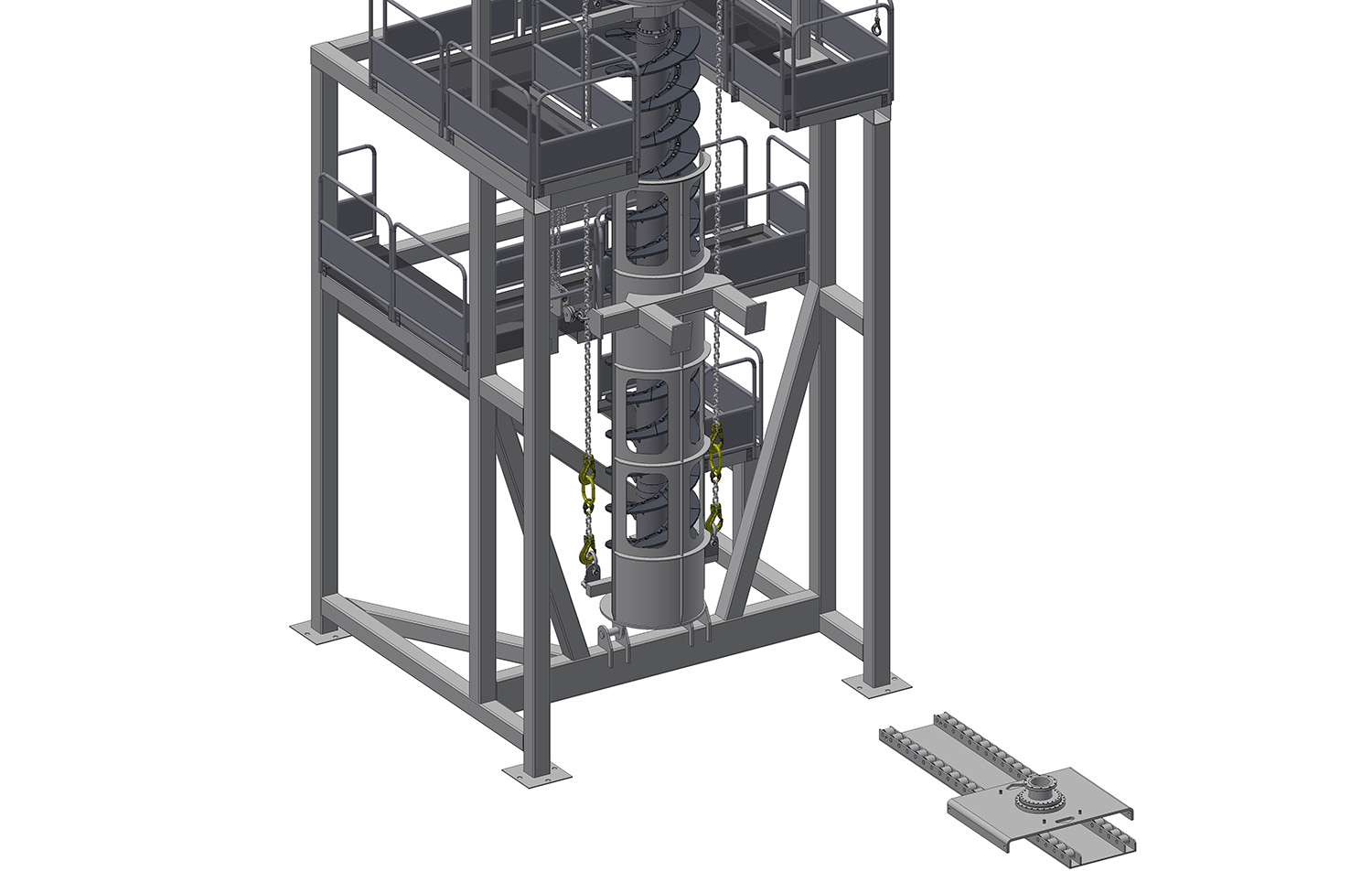

The tower’s structure is self-supporting, allowing it to be moved. When required for a project, it needs to be secured at dedicated fixing points on the jetty. A replacement screw is placed and fitted into the tower’s lowered screw-holding cradle, specifically matched to the dimensions of the screw. A winch raises the cradle and screw into an upright position. When in place, the new screw is locked into position and the outer diameter bearing wings are assembled. The same procedure is repeated with the next screw section. Removal and disassembly of the screws are achieved using the same equipment, but in reverse.

“Although specifically designed for screw replacements, it can also be built with additional levels to service and inspect other areas of the vertical conveyor,” notes Mr Ohlsson. “For any new or existing unloader, this is an extremely cost and time effective addition to any operator’s service portfolio.”

By using adaptors, the service tower can accommodate the various screw lengths and sizes of the Siwertell product range.

Please contact us for more information

Bruks-Siwertell

Bruks-Siwertell