Consign crushed grains to the past

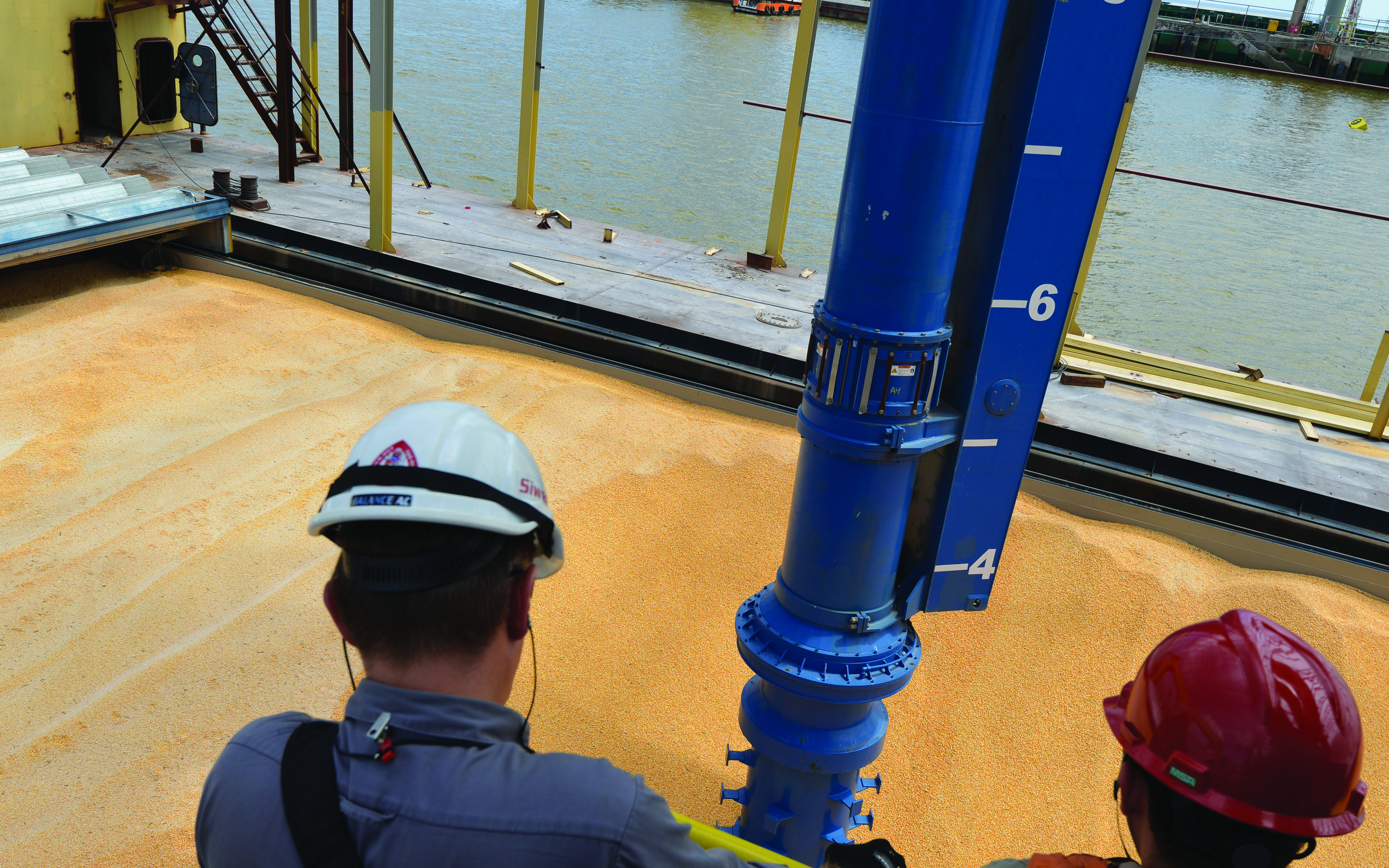

19 Sep 2018It is possible to handle grains so carefully, efficiently and quickly that importers can benefit from a significant competitive edge; Peter Göransson, Sales Manager and Senior Advisor for Siwertell explains how

Growing food demands, stricter environmental requirements and a serious lack of tolerance to waste are all features of today’s modern bulk grain terminals. These dictate that operators must now consider their most efficient options on the market, particularly when investing in new systems.

Importers no longer have to settle for inefficient grain-handling technologies that can damage and potentially down-grade shipments, or for a system that spills and wastes cargo and pollutes the immediate port environment, particularly not when all of these can be avoided.

Systems that speak for themselves

Of course we are going to say that our systems are the best on the market, but we have sound evidence for this claim.

Siwertell is the only manufacturer of grain-unloading systems that can deliver a continuous rated capacity of up to 2,000t/h with minimal environmental impact, and handle grain gently enough that degradation and crushing are virtually eliminated. Siwertell’s grain-handling attributes also include the highest continuous rated loading capacities, which are in excess of 3,000t/h.

The same machines can handle soya beans, meals and other non-free flowing foodstuff materials at these high capacities; another major advantage of Siwertell technology.

Our high-capacity systems are also generally more compact, lightweight and quieter than alternatives with similar rated capacities. This delivers benefits in terms of load-bearing requirements and lower investment costs for new jetties. The quiet nature of Siwertell units enables operations in very close proximity to populated areas.

Optimised solutions for ports

For operators looking to add grain-handling capabilities to a terminal, without incurring any major permanent infrastructure costs or for smaller-scale import operations, we have recently introduced a standardised port-mobile unloader. This was developed as a result of our on-going investment in technological research to ensure that we continue to meet the needs of the grain-handling industry.

In particular, we believe its introduction challenges traditional port-based pneumatic systems. It offers similar rated capacities, however unlike pneumatic systems, the vertical screw-type conveyor is able to manoeuvre within a hold, even under the hatch openings. It also handles cargoes very gently, virtually eliminating any damage to grains. These factors alone make it an extremely efficient, cost-effective option. Add in the fact that it uses standardised components and this further increases its cost-efficiency.

The new unloader is optimised for port use and is available as a 400t/h or a 600t/h unit; able to discharge vessels up to 60,000 dwt. It has a stable, lightweight steel structure and benefits from the many proven capabilities of our popular road-mobile systems, in addition to demonstrating unique attributes of its own.

Responsive, intelligent technology

Equipped with a self-propelled rubber-tyre system and an advanced steering solution for easy manoeuvrability between operations, the port-mobile unloader can travel straight ahead, in reverse or diagonally, both to the left and to the right. It is also able to smoothly rotate up to 30 degrees both left and right.

The port-mobile unloader discharges grain directly to trucks via a dual truck-loading system as standard, however there is an option for a third. As these systems are independent of each other, it is totally flexible during truck loading, delivering the fastest loading operation possible and maximising efficiency.

To minimise the impact of truck changeovers, the unloader is also equipped with a large-volume intermediate surge hopper, allowing discharge operations from a ship to continue even if no trucks are available immediately.

Benefits of a gentle approach

So why must an unloader use a light touch while handling grain? Well, it is all about the production of powdery fragments, smaller than the grain particles themselves, known in the business as fines.

Fines are problematic for many types of cargo, but in grain-handling they can make the grain more difficult to aerate and increase spoilage rates and dust emissions. Under some circumstances high levels of fines can result in a dusty atmosphere, raising the risk of fire and explosions.

Fines also have to be removed before milling; therefore their presence has a significant knock-on effect on grain processing as a whole. A high level of fines in a grain shipment can also mean that the quality of the shipment is down-graded.

Siwertell screw-type technology achieves extremely low damage rates to grain shipments because it handles the grain very gently. Cargo flow speeds in the vertical conveyor are relatively low, which translates into fewer collisions between cargo particles during conveying, resulting in a very low level of fines production.

Tests undertaken with third-party inspection companies have proven that Siwertell’s screw-type technology causes next to no degradation of unloaded material.

PLEASE CONTACT US FOR MORE INFORMATION

Categories: Bulk unloading

Bruks-Siwertell

Bruks-Siwertell