How to get the best from your ship unloader

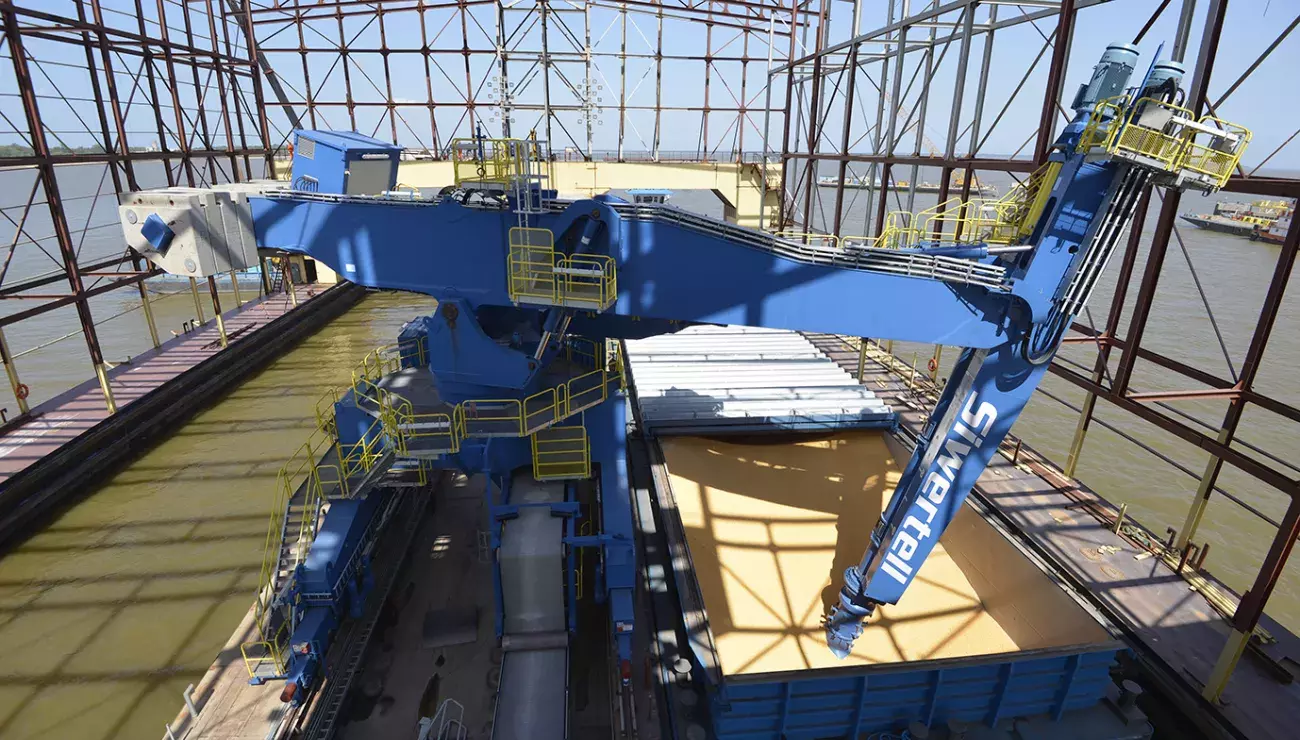

4 Oct 2017A Siwertell unloader is a major investment and you’ll naturally want it to deliver the best performance throughout its long working life. It is a great machine, but like any other industrial plant, it needs proper maintenance and operating protocols to deliver its full potential.

We naturally provide full operating instructions and maintenance recommendations with every new delivery, aimed at ensuring effective service strategies, good operator training and the timely replacement of wear parts.

For the busy manager, here are some top tips that can be used for a quick review of the regimes applied to an unloader. They may confirm that everything is running well; or they may identify areas that would benefit from further consideration.

Minimize wear and avoid damage

The vertical conveyor can be operated at an angle to the vertical to reach into corners and under hatch coamings. However, flexible operation in this mode may increase the wear rates of certain components, so operators should develop unloading plans designed to minimize the time spent out-of-vertical.

Great care must be taken during out-of-vertical operations, because they unavoidably expose the inlet feeder to an increased risk of damage, especially the possibility of bending the inlet wings by striking bottom of the hold. If this happens the wings should be adjusted back to their normal position to restore the unloader’s full capacity.

Communications and cooperation

As the level of cargo in the hold falls it is important to work in close conjunction with the excavator/pay loader, moving material as early as possible to ensure that the vertical conveyor continues to operate at full capacity for as long as possible. Good communications and cooperation between the pay loader and unloader ensure maximum efficiency and minimize final clean up requirements.

It is important to avoid impact between any part of the unloader and the ship’s structure. We recommend guidance from additional personnel to give a good view of the equipment and its surroundings when unloading close to ship structures.

Proper maintenance pays dividends

Proper maintenance is essential for your unloader. Encourage operators to report any abnormal vibrations or noise as soon as they occur. Early attention will avoid excessive wear and remove the risk of more serious damage.

Regularly check the conditions of bearings, including the outer diameter (OD) support bearings. Make sure that the play in the OD support bearings is within limits; excessive play can result in increased wear in the vertical conveyor and must be rectified as soon as possible.

If you have an unloader equipped with a centralised greasing system, check regularly for blockages and ensure that grease is emerging from every greasing point. Keep the shipunloader clean and ready to use. Safety systems and equipment should be serviced regularly according to the maintenance manual.

Don’t lose time waiting for a spare part

Keep your stock of spare parts up-to-date in line with the spare parts inventory recommendations. Having critical and wear parts readily available on site minimizes downtime in the event of a component failure.

We’re always pleased to hear from you

If you have any questions regarding unloaders or related equipment, do not hesitate to contact us.

PLEASE CONTACT US FOR MORE INFORMATION

Categories: Bulk unloading

Bruks-Siwertell

Bruks-Siwertell